ConstructLane

The smartest way to control modular construction projects for quality compliance and e-handover

The smartest way to control modular construction projects for quality compliance and e-handover

With our skid design services, mobile-first tech for enforcing project quality compliance workflows, and localized BIM-based 3D inspection services, your team gains unprecedented control and visibility over material and fabrication as they unfold at the shop floors anywhere in the world.

Vendor-direct pricing for all your process module projects across 1,000+ factories and suppliers worldwide.

Whether you want to source at complete module level or source directly at the components level, we've got you covered.

Powerful project sourcing & workflow controls built for owner handover from day one.

End-to-end visibility and project controls into your supply chains and project lifecycles. From design, procurement, construction to maintenance.

Dedicated process module experts who operate as an extension of your project team covering your entire project lifecycles

Acess to vetted experts in VDC, shop design, 3D/4D BIM, kitting, inspections, qualification, and maintenance services.

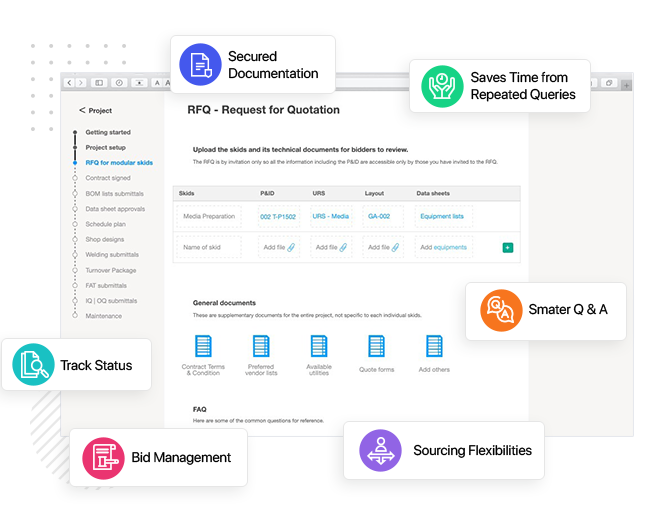

Brings your RFQ out of siloed emails, scattered spreadsheets and documents, and into a collaborative yet secured online space.

Get live bids for your structured RFQ, run smarter Q&A without repeats, complete contracts online and track status. Integrate with your bid management systems.

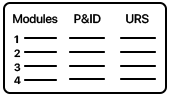

Your engineering firm can even create a streamlined equipment list with our data sheet generator that is fully traceable to each and every modular systems. All tag #, datasheet # and skid # are automagically matched up.

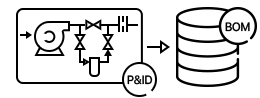

Organize your RFQ documents by uploading P&ID and their equipment data sheets to get fast and accurate bids from vendors.

Run all Q&A logs with document-based context for clarity and saves time from repeated queries. Your engineering firm can even create a streamlined equipment list with our data sheet generator.

Get the best pricing directly from vendors. Invite your preferred vendors or add a few others to see your options.

Contracts are ready-to-go with guided legit online signatures with approval workflows. Smart bar highlights where to sign.

Simplify the bids further with our front end Smart P&ID services to get a fully detailed BOM database and weld lists sync to your P&ID.

Stop counting the valves and instruments manually with pencil highlighters and then trying to group them up with Excels hoping that it matches with the evolving P&ID.

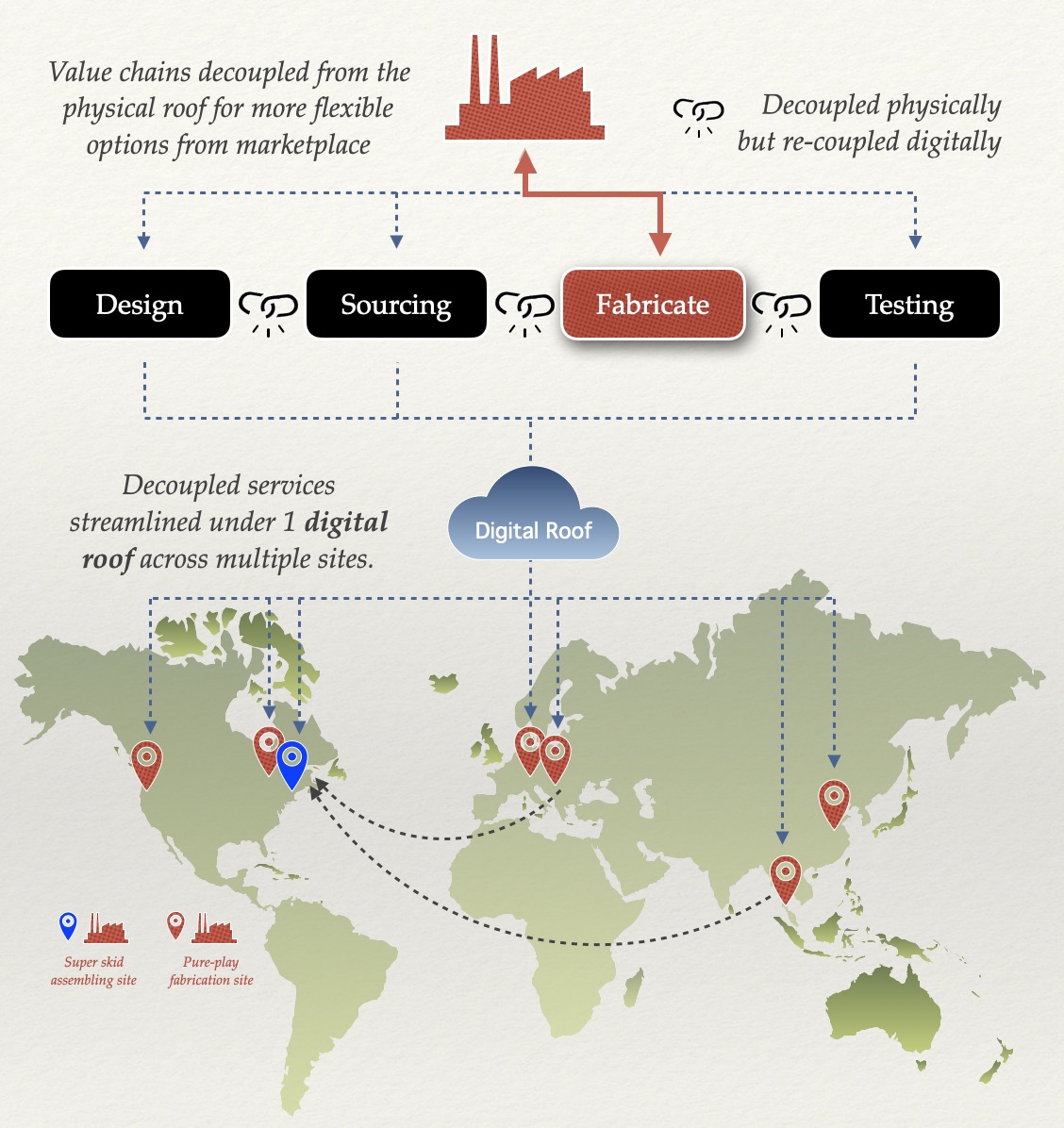

“Source design and materials centrally for consistency and scale,

but split the build locally for speed”

Gain speed without losing scale by decoupling materials from construction.

How to speed up mega projects without breaking the bank? Ramping up capacity isn’t sustainable. The future points to shared modular build approach.

With our Smart P&ID services, you can now source design and materials centrally from vetted providers for consistency and scale. And send it to multiple fabricators for faster lead time.

All the value chains get streamlined under one digital roof replacing the physical roof of a typical factory.

Simplify the job even further with our Ikea-style kit services. Fabricators receives assembling-ready kits with QR code access to latest drawings. It doesn’t get any simpler and faster than this.

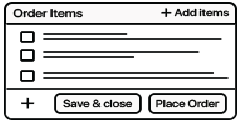

Your orders are automatically split into POs for each relevant vendors, so you can go into production more quickly.

Split materials shipments from a single order to multiple fabrication sites to speed up project delivery.

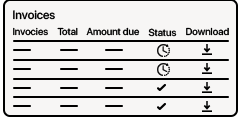

Know how much is due, and when. Your payment terms are tracked in ConstructLane giving you visibility and predictability on all payments.

Simplify your accounting with flexible online payment. Issue batch payments to pay multiple invoice at once, or split your payment across multiple bank accounts.

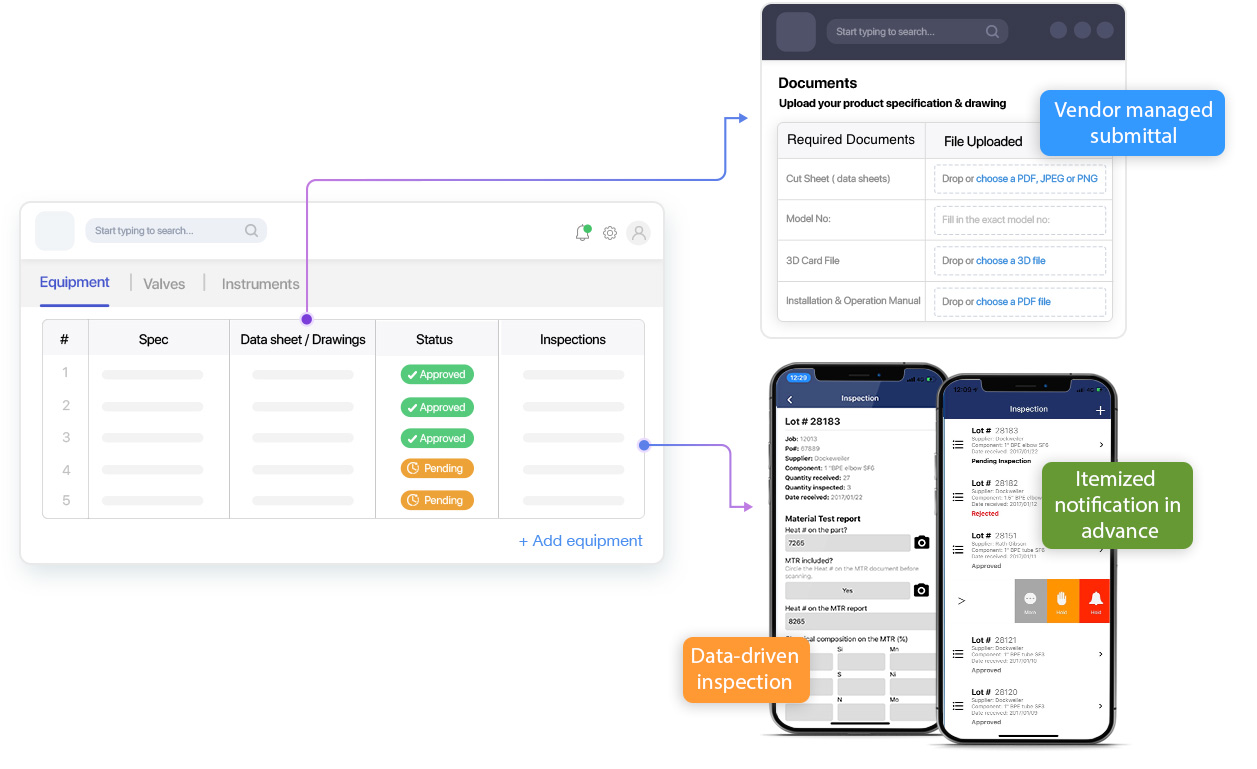

Let our workflow drive the vendor document requirement process so that you get peace of mind nothing is missed, incorrect, left to chances. Collect them like IRS do with taxes.

Tracking hundreds of submittals, RFI, and change orders from multiple vendors with thousands of data points using manual processes is a true nightmare for downstream qualification and maintenance. You don’t even know what you’ve missed until it is too late. Get it right from the get go.

Every aspect of your material is captured in intricate detail with our powerful specifications data format. Specs help you speed up quoting, avoid production errors, streamline inspection and qualification accuracy and much easier maintenance.

“Manage the material compliance like its on rails.

Do it right from the start for the end game: operation and maintenance”

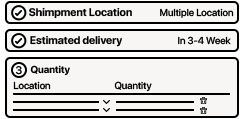

Upload the bill of materials to an online database to manage its lifecycles from data sheet approvals, ordering, receiving & inspection, and maintenance logs.

Configure submittal requirements for each material category and let the workflow drive the compliance and approval process like clockwork.

Overview of the entire BOM status with filters and sorting to focus your precious attention or create meeting agenda.

Our inspection services can be deployed at vendor’s site instead of catching problems much later in the process causing lead time disruptions.

Industrializing Construction with Industry 4.0

“Don’t move information to the management, move management

to the information where activities are really happening “

With services industrialized, materials prequalified, sorted into kits, and workflows digitized, a shared modular build approach becomes an effective way of cutting lead time.

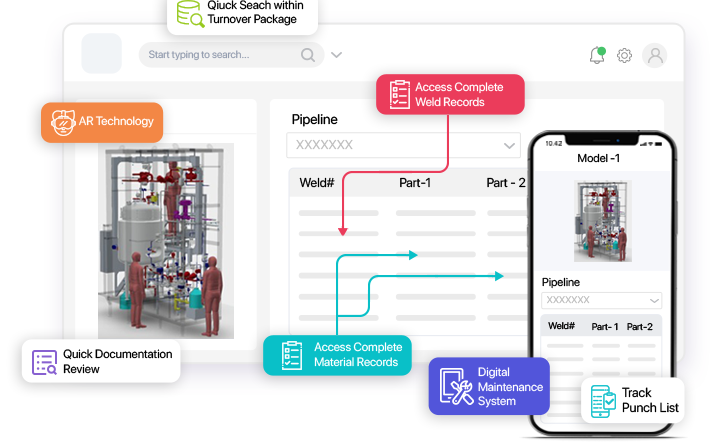

With the approved shop design and precon planning uploaded to our mobile app platform, Lean workflows and controls are followed across all fabricators with utmost consistency.

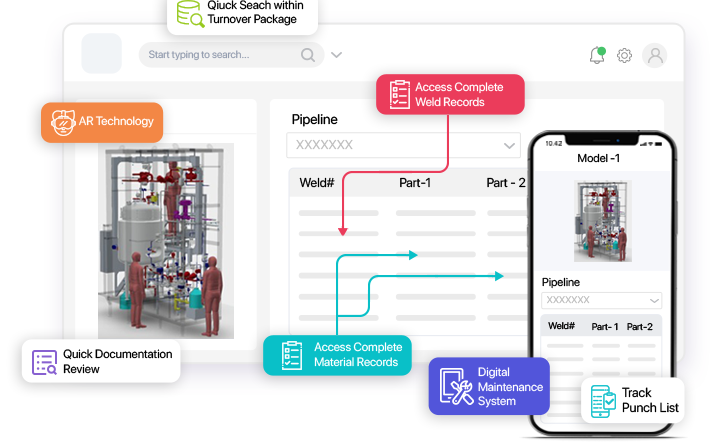

Access drawings with “digital twins“, work-order queues next in line, follows instructions for QA compliance. Capture digitized weld log and inspection records in real-time with authentication blocking unauthorized welders and WPS for controlled work. All in the mobile apps.

Not even the foreman had this much control over the shop floor before ConstructLane.

Upload the weld lists of all approved shop design with 3D models and it's ISO drawings to our online database.

Manage construction drawings and precon such as procedures and qualification reviews and approvals on the platform.

Use our kitting services to drive consistency and replace error prone material requisitions across multiple fabricators.

Each welds are authenticated with basic metadata that includes time, place, welder, weld #, WPS..etc.

At ConstructLane, projects are sourced and built for owner handover from day one.

Every item sourced on the platform goes through it’s pre-configured workflow to meet qualification and maintenance needs. Everything is captured in the database in due time. No more compiling turnover packages at the very end of the job.

Imagine how easy and powerful it can be to qualify and maintain a system with a digital twin backed by a database? If you can check the BIM model with AR technology and click the components to see its technical details, data sheets, maintenance history, issue repair orders? It’s already here.

Want to digitize your exiting equipments and facilities? Book our 3D experts to scan, rebuild, and integrate your digital twins to your CMMS and or BMS so you can enjoy fast and accurate retrieval of equipment information to stay safe, compliant, and achieve high OEE.

“Stop flipping through mountains of paper

and get your job done quickly with our powerful database

purpose-built for qualification and maintenance ”

Review all your qualification protocols for approvals. Benefit from connectivity between protocol and BIM database.

Easily find the traceability for materials and welds in a user-friendly database.

Visualize which equipment or components need maintenance with BIM model and AR technologies.

Two way Integration between the BIM and its BOM database to leading CMMS - Computerized Maintenance Management System.

Manage every aspect of your project supply chain, with smart end-to-end software.

Reduce your construction costs with transparent, manufacturer-direct prices from vetted factories and vendors.

Work with modular skid and supply chain experts who operate as an extension of your team.

Get started with ConstructLane

Email: contact.us@constructlane.com

Everyone knows that a typical skid project easily involves hundreds if not thousands of documentations. Capturing them completely and making sure they are indeed correct with data integrity using the current paper based processes is a huge challenge and error prone. Authenticating that welders, WPS, and machines used for each weld are authentic has not been easy especially for project owners. And the entire workflows for material and welding controls do not have much visibility at all. All told, the control over the shop floor is weak.

In short, all the inefficiencies from the build phase are absorbed by the downstream operation and maintenance, a phase that isn’t always a top priority for builders.

ConstructLane helps owners and contractors simplify what could be a very complex and fragile project delivery: starting with spec-driven sourcing followed seamlessly by workflows that tracks every material and installation / fabrication for QA compliance. And brining visibility to the entire project delivery process along its lifecycles. Seeing the progress of each material and fabrication (welds) online as they unfolds in the field. Basically, staying in control as if you are there in person.

The industry still relies too much on qualification as quality reassurance. We need more Edwards Deming’s focus on the upstreams of the project lifecycles .

Making sure that every item (both material and installation) indeed went through the due diligence of qualification and documentation. Not a single item is missed and all the qualifying criteria are indeed captured, verified and documented accurately.

Collect all documents that is owed to the project IRS style.

At owner handover, allowing users to operate and maintain their systems with a clean web and mobile interface backed by a powerful database that is easy to use. And help them find the equipments or components details and histories with technologies like Augmented Reality AR + BIM to get their job done quickly. A 3D digital turnover package on CMMS steroids if you will.

This is something that is long overdue and is what the next generations of engineers & operators have come to expect based on their daily B2C experiences. Now it’s time for B2B experiences to be just as simple and fast.

This is our humble vision and burning passion for our users in the AEC world.